CNC machining processes can produce high-quality parts faster, within tighter tolerances, and with higher repeatability rates than manual machining operations. Tanfel provides the raw materials and machining expertise necessary to bring your product designs to life.

CNC Machining Capabilities

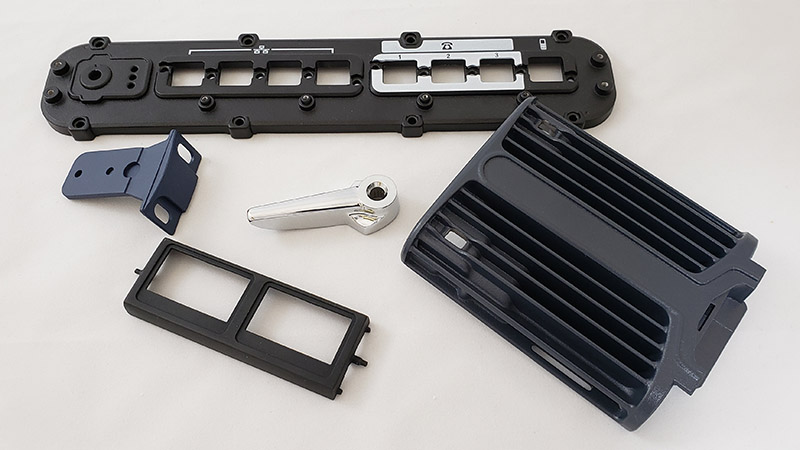

Computer numerical control (CNC) machining is a broad term encompassing an expansive range of automated machining processes. At Tanfel, our CNC machining capabilities include:

CNC Milling

We offer CNC milling services for both prototyping and full production runs. Our facility maintains a fleet of 3-axis, 4-axis, and 5-axis machines that can create complex and intricate products with spindles and machining tools that operate along the X, Y, and Z axes. These machines facilitate simultaneous cuts on the varying axes for faster production and more complex shaping.

Tanfel’s CNC milling capabilities include the following:

- Broaching

- Drilling

- Electrode and wire EDM

- Honing

- Jig boring

- Laser machining

- Milling

- Screw machining

- Turning

Our specialty milling processes include jig or fixture manufacturing, casting machining, tool and die manufacturing, and rotary transfer machining. Our team of technicians and engineers will help you select the best processes for each part and stage of production.

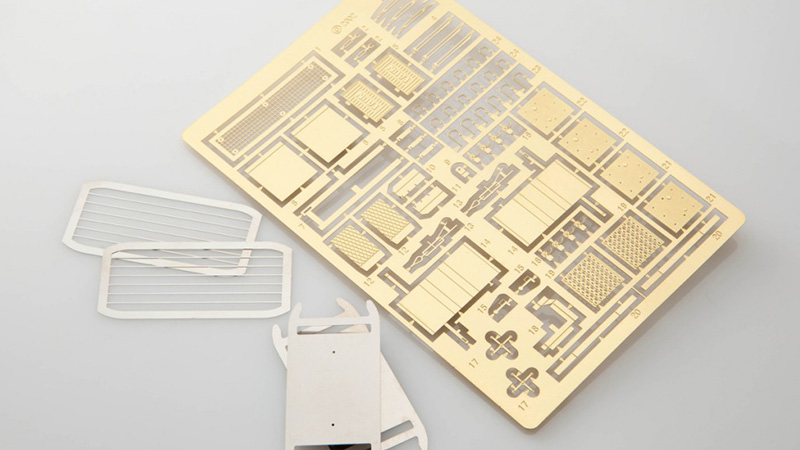

CNC Turning

CNC turning is a machining process used to create cylindrical objects. This reductive process rotates the workpiece on its axis while a linear cutting tool removes material from the surface. Our turning capabilities work within tolerance levels of ± 0.00008 inches to ensure excellent dimensionality and fit within complex part arrangements.

Tanfel offers CNC turning services for parts with diameters up to 15 inches and lengths up to 120 inches. We use the following types of CNC lathes and CNC turning machines:

- Bench lathe

- Center lathe

- Multi-spindle lathe

- Screw machines

- Swiss style

- Swiss turning center

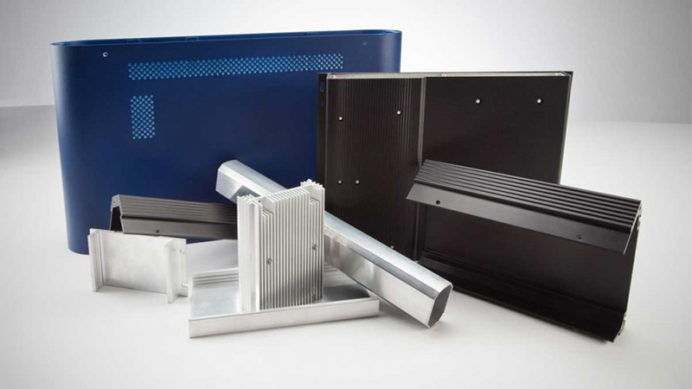

Available Materials

Tanfel also provides access to a broad range of raw materials. We source metals and alloys from reliable third parties and maintain an extensive inventory on-site. By providing materials directly, we streamline the production process by limiting the number of necessary vendors our customers must work with. Our inventory of metals and alloys includes:

- Aluminum is a lightweight, non-magnetic metal that can be easily formed or drawn.

- Brass is a non-magnetic copper-zinc alloy that is easy to machine and cast. Common applications for brass include decorations.

- Bronze is a non-magnetic copper-tin alloy that is ductile, resistant to corrosion, and comes in multiple specialized varieties.

- Cast iron is hard and strong but features a relatively high degree of elasticity.

- Copper is a non-magnetic metal that can be easily drawn, is an excellent conductor, and resists corrosion.

- Hardened metals have been heat-treated for additional exterior hardness and damage resistance.

- Nickel is a hard, corrosion-resistant metal that can be magnetized.

- Nickel alloys, which include nickel-iron alloys, nickel-copper alloys, and nickel-molybdenum alloys.

- Steel is a carbon-iron alloy with many different variations designed to strengthen core properties, such as conductivity, ductility, or resistances.

- Stainless steel also contains chromium and has excellent resistance to corrosion.

Other materials can be successfully used with CNC milling and turning processes as well. Depending on the nature of your product and its intended applications, you can also request machining processes for different varieties of plastics and ceramics.

Industrial Applications

Every industry uses CNC machined parts and components in some form. Some of those industries include:

- Aerospace

- Consumer goods

- Electronics

- Firearms

- Military and defense

Advantages of CNC Machining

In CNC machining processes, the equipment follows precise sets of instructions derived from product design files to create identical parts. CNC machining offers more precise machining, a higher degree of replicability within tight tolerances, and a much lower risk of human error or injury.

Quality CNC Machining Services at Tanfel

Tanfel has produced high-quality custom parts for customers in a broad range of industries and applications for more than 10 years. Our team can support your project from initial design through quality control and inventory management.

Whether you need high-quality prototypes or a full production run, contact our team or request a quote for more information about our CNC machining capabilities.