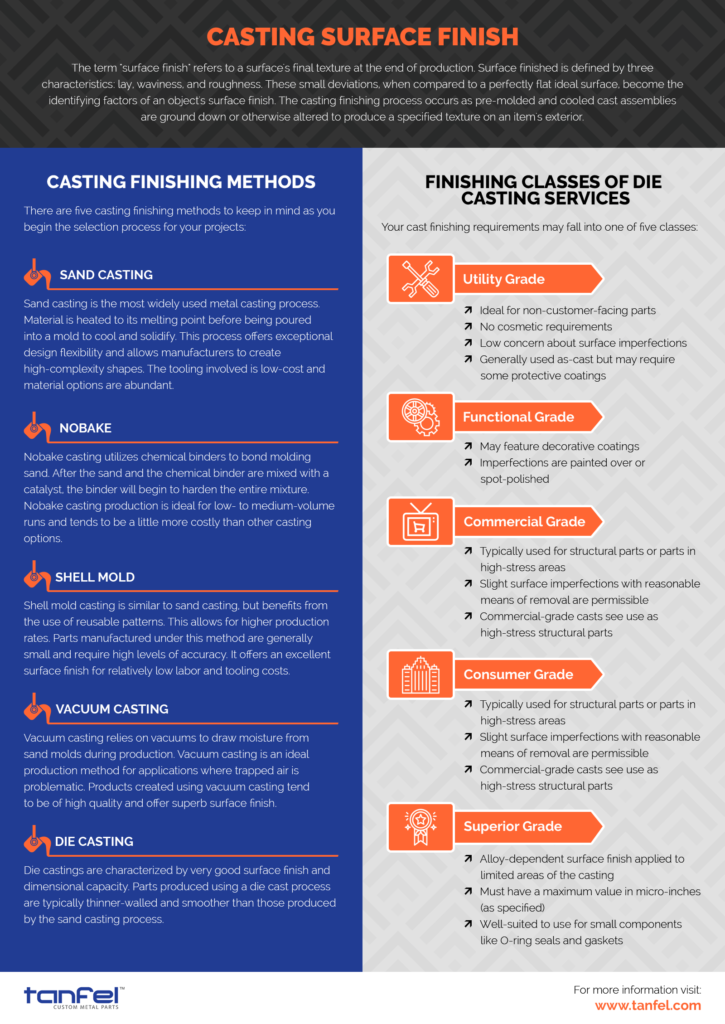

Casting Surface Finish

The term “surface finish” refers to a surface’s final texture at the end of production. Surface finished is defined by three characteristics: lay, waviness, and roughness. These small deviations, when compared to a perfectly flat ideal surface, become the identifying factors of an object’s surface finish. The casting finishing process occurs as pre-molded and cooled cast assemblies are ground down or otherwise altered to produce a specified texture on an item’s exterior.

American Foundry Society shows surface finishes from 20 to 900 RMS.

Casting Finishing Methods

There are five casting finishing methods to keep in mind as you begin the selection process for your projects:

-

Sand Casting

Sand casting is the most widely used metal casting process. Material is heated to its melting point before being poured into a mold to cool and solidify. This process offers exceptional design flexibility and allows manufacturers to create high-complexity shapes. The tooling involved is low-cost and material options are abundant.

-

Nobake

Nobake casting utilizes chemical binders to bond molding sand. After the sand and the chemical binder are mixed with a catalyst, the binder will begin to harden the entire mixture. Nobake casting production is ideal for low- to medium-volume runs and tends to be a little more costly than other casting options.

-

Shell Mold

Shell mold casting is similar to sand casting, but benefits from the use of reusable patterns. This allows for higher production rates. Parts manufactured under this method are generally small and require high levels of accuracy. It offers an excellent surface finish for relatively low labor and tooling costs.

-

Vacuum Casting

Vacuum casting relies on vacuums to draw moisture from sand molds during production. Vacuum casting is an ideal production method for applications where trapped air is problematic. Products created using vacuum casting tend to be of high quality and offer superb surface finish.

-

Die Casting

Die castings are characterized by very good surface finish and dimensional capacity. Parts produced using a die cast process are typically thinner-walled and smoother than those produced by the sand casting process.

Among these, sand casting processes typically produce rougher surfaces. Chemically bonded processes such as nobake or shell can have a similar finish to ceramic processes. Shell sand can produce a range finish on average RMS values of 75-150, vacuum casting 150-200 RMS. Diecasting and squeeze casting both can reach 20 RMS in extreme cases.

Material selection also impacts surface finish for castings. When weight and section thickness increase, surface finish quality decreases. Alloys with higher melting points produce lower quality finish than alloys with lower melting points. Aluminum will have a smoother finish than iron or steel castings.

For mold casting, the quality of the tool is critical to achieve the best surface finish. Proper die maintenance is also important for a consistent finish.

Finishing Classes of Die Casting Services

Your cast finishing requirements may fall into one of five classes:

Utility Grade

- Ideal for non-customer-facing parts

- No cosmetic requirements

- Low concern about surface imperfections

- Generally used as-cast but may require some protective coatings

Functional Grade

- May feature decorative coatings

- Imperfections are painted over or spot-polished

Commercial Grade

- Typically used for structural parts or parts in high-stress areas

- Slight surface imperfections with reasonable means of removal are permissible

- Commercial-grade casts see use as high-stress structural parts

Consumer Grade

- High-class decorative coating

- No noticeable surface imperfections

- Generally produced with the end goal of being special decorative parts

Superior Grade

- Alloy-dependent surface finish applied to limited areas of the casting

- Must have a maximum value in micro-inches (as specified)

- Well-suited to use for small components like O-ring seals and gaskets

Casting Finishes at Tanfel

Tanfel offers clients a variety of finishing process options for casted parts. We can use abrasive blasting to smooth a rough surface. Abrasive blasting using materials like sand and glass beads produces smooth finish at a lower cost for clients. Abrasive blasting elevates good finishes to an even higher quality. We also offer a range of secondary machining services to provide additional finishing options.

Our knowledgeable, professional staff will be glad to speak with you about your individual needs and create a plan custom-tailored to provide you the solutions you’re seeking. Contact us or request a quote to learn more about our finishing capabilities for castings.